Video

Video

The stainless steel filter tube/cylindrical filter tube mainly material is stainless steel sintered mesh, stainless steel woven mesh or stainless steel fiber sintered felt.

The filtration accuracy is 25-200μm.

It has many good characteristics, such as good permeability, high strength, strong corrosion resistance, easy cleaning and anti-cleaning, not easy to damage, no material separation, etc.

Stainless steel filter tube, stainless steel filter tube 304, stainless steel filter tube 316, stainless steel filter tube, stainless steel punched filter tube.

Materials: SUS302, 304, 304L, 316, 316L, etc., single layer, multiple layers.

Specification: 1x1-635x635 mesh

Size: can be customized

Weaving method: plain weave, twill weave, mat weave, mat twill weave

Style: welded by stainless steel mesh, stainless steel punching mesh, iron mesh, stainless steel plate and iron plate. It can be single-layer welding, multi-layer welding, and after single-layer welding, the metal filter mesh tube, mesh tube, mesh barrel, filter element and filter tube are overlapped and inserted together to form multi-layer filtration.

Advantage:

Wear resistant

2. High temperature resistance

3. Strong acid resistance

4. Corrosion resistance

Use:

1) Catalyst filtration and separation;

2) Filtration of high temperature gas in petrochemical industry, filtration of tail gas in boiling bed of petrochemical plant, filtration of catalytic cracking slurry;

3) purification of high temperature flue gas in the metallurgical industry;

4) Filtration of other high temperature gases and liquids;

5) Filtration of various high temperature, corrosive liquid and catalyst in the petrochemical industry;

6) Filtration and purification of various polymer melts in the chemical fiber film industry;

7) Filtration and separation of various catalysts in the pharmaceutical industry;

8) for gas distribution, liquidized bed orifice material;

9) for high pressure backwash oil filters, etc.;

10) various slurries for filtering edible oils, beverages and food;

11) used to purify and filter production wastewater

Production process: through the cutting board - roll round - welding - rounding - surface treatment - forming

-

304 stainless steel test sieve

-

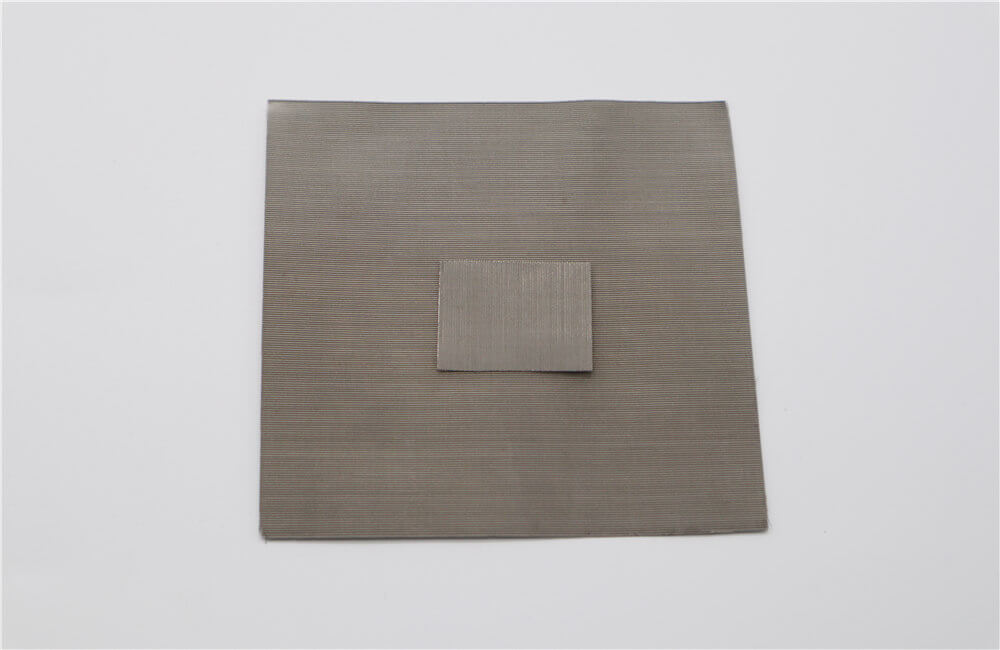

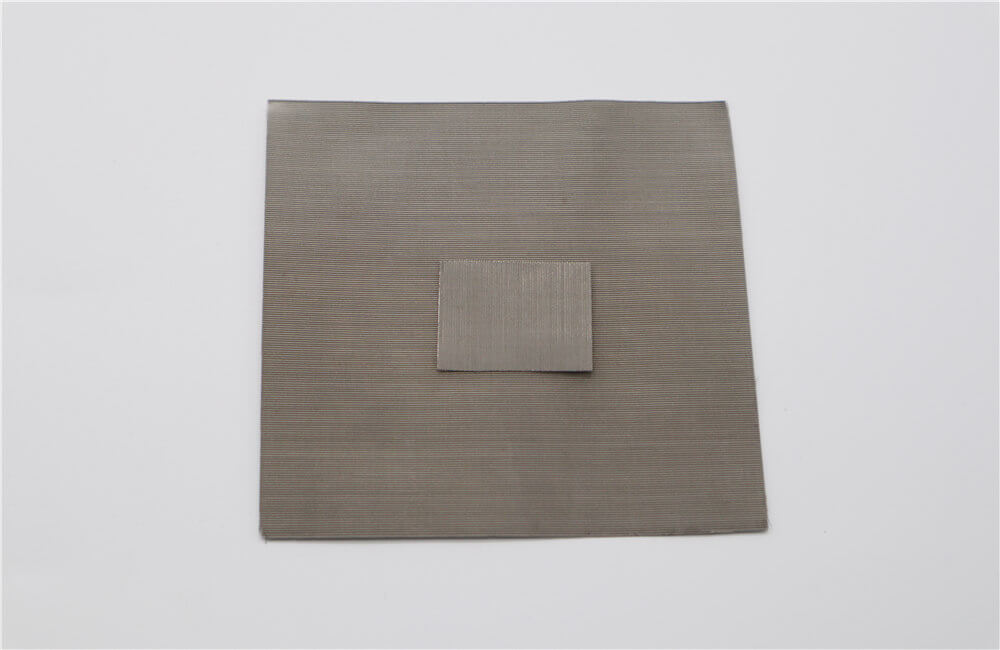

Stainless Steel Cutting Filter Mesh

-

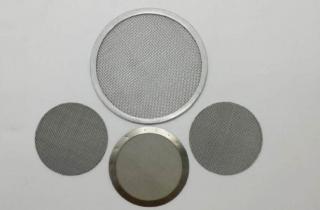

Stainless Steel Filter Disc

-

Stainless Steel Filter Disc

-

Stainless Steel Filter Disc

-

Stainless Steel Filter Disc with edge covered

-

Stainless Steel Filter Tube

-

304 stainless steel screen filter mesh